Drilled Shaft Defects

The objectives of this research are to determine what are the smallest defects that can be located using the available Non-Destructive Testing (NDT) methods, and the effect of defects on the axial capacity of Drilled Shafts.

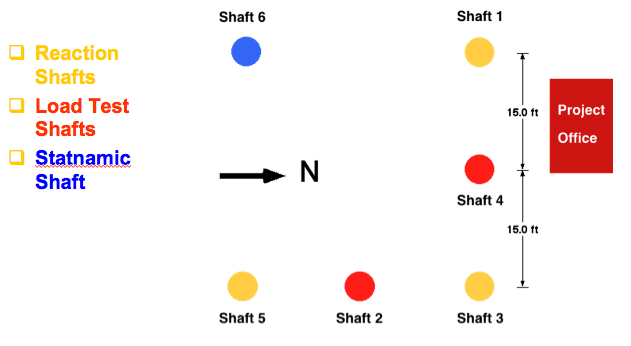

Six 3-ft. diameter 60-ft. long shafts, with built in defects, were constructed at the National Geotechnical Experimentation Site in Amherst, MA.

Defects included voids and soil inclusions occupying 5–45% of the cross section as well as a soft bottom. The site geotechnical condition consisted of 12 feet of over-consolidated crust having OCR=6-10 and N=5-15 under lying by soft grey Connecticut Valley varved clay.

Nine organizations participated in a blind defect prediction symposium, using a variety of NDT techniques. Most participants located defects that were larger than 10% of the cross sectional area. However, false positives and inability to locate smaller defects and multiple defects in the same shaft were encountered. Static load tests indicated that (1) minor defects had little or no effect on skin friction; (2) a soft bottom resulted in a 33% reduction in end bearing relative to a sound bottom; and (3) reloading resulted in a 20–30% reduction in the geotechnical capacity.